Automatic disposal

A modern spinning mill is very capital-intensive. For this reason, a 100% efficiency is the goal. Highly productive spinning machines require production conditions that are as constant as possible in order to achieve optimum performance. A large number of spinning stations can reduce the average investment costs. As the length of the spinning machines increases, the need to empty the filter boxes also increases. The larger a production plant, the longer the transport routes. These are just a few points that need to be considered when designing the secondary material cycle.

A manual solution is labor-intensive and carries the risk of unreliability. However, reliability has a very large influence on a wide range of production factors. By automating the outgoing logistics using a central vacuum system, you increase the reliability of the process and thus the efficiency of your production.

Proven solutions for automatic disposal of:

- Rotor spinning machine outlets

- Winding machine outlets

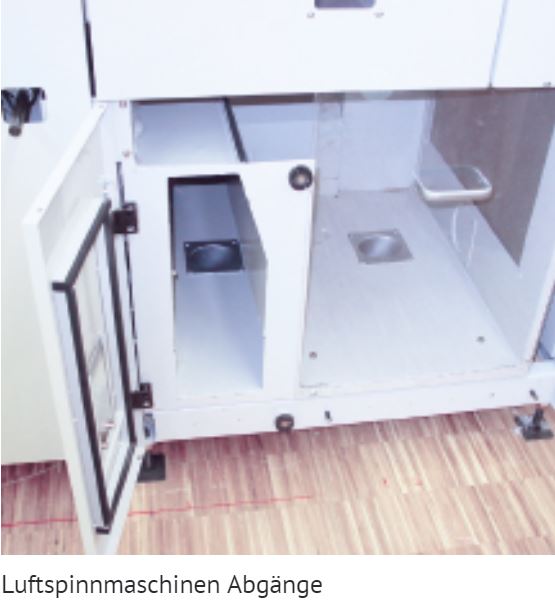

- Air spinning machine outlets

- Dust collectors

- Fiber separators

- Waste separators

- Traveling cleaners

With our system, customers have achieved the following effects:

- Increase productivity by 1%

- Reduction of energy consumption of production machines

- Quality improvement and reduction of quality fluctuations

- Up to 20% less yarn breakage

- Reduction of manual interventions by personnel, increase reliability, reduce costs

- Fewer production interruptions and reduction of maintenance times

- Reduction of spare parts requirements for production machines

In addition to a short payback period, our systems are characterized by the following advantages:

Fully automatic operation

Low energy costs

Minimal and easy maintenance

Comprehensive cleaning range

Easy installation of the compact cable network

Extensions or modifications to the system are possible at any time

Contact us and describe your needs to us. A system from us can also optimize your production.

Contact information

Steinemann Central Vacuum Systems

Wilerstrasse 2180

9230 Flawil

Schweiz

Tel: +41 71 394 14 14

Fax: +41 71 394 14 83